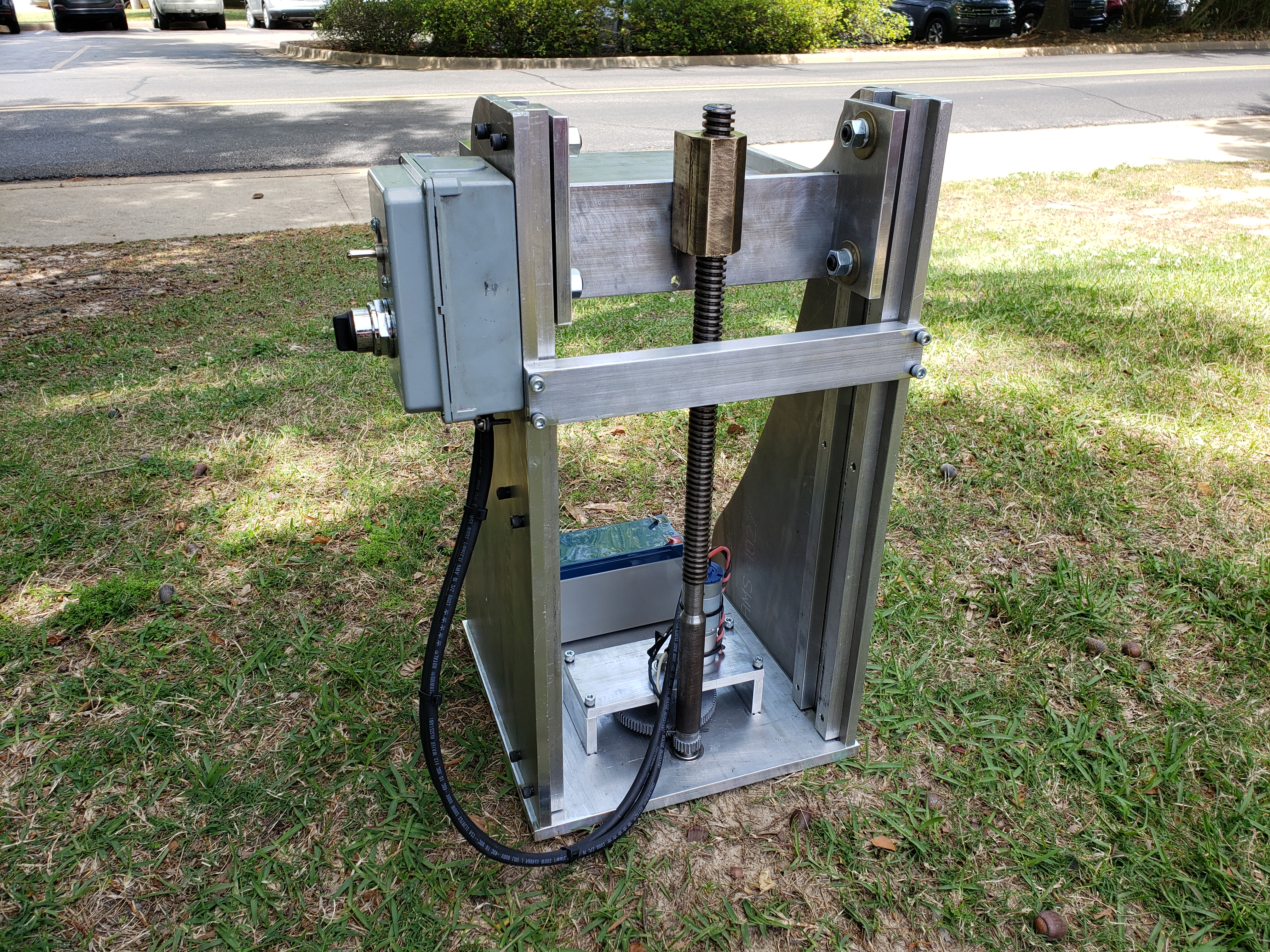

Motorized Lifting Jack with Gear Assembly - Team Lead

To view the Presentation for this project, CLICK HERE:

The purpose of this project was to design a lifting mechanism that could lift a minimum of 1kg, but there was a competition for which team could lift the most. With this design, using a gearbox and threaded rod, we were able to lift over 100 kg, and took 1st place in the competition! Not only did we lift the most weight, but we were also commended on the robust design and skill in manufacturing.

Initially, a design was formed and modeled in SolidWorks:

Another aspect of this project was verifying our results using Finite Element Analysis. This was accomplished using ANSYS, as well as SolidWorks, to show the stresses and strains that our product could endure.

The following photos show the displacement with a 2.2 lb load and 100 lb load, respectively:

Then the Factor of Safety was modeled and calculated for both the 2.2 lb and 100 lb load, respectively:

Animation of the FEA in ANSYS:

This project was a real test of the skills I had learned up to that point. Not only designing and modeling the device, but also performing FEA to ensure that it would perform. The manufacturing of the product was more in depth than my teams had faced up to that point, but through excellent teamwork we not only surpassed my own expectations, but proved to be the most successful team!